Filterboxes

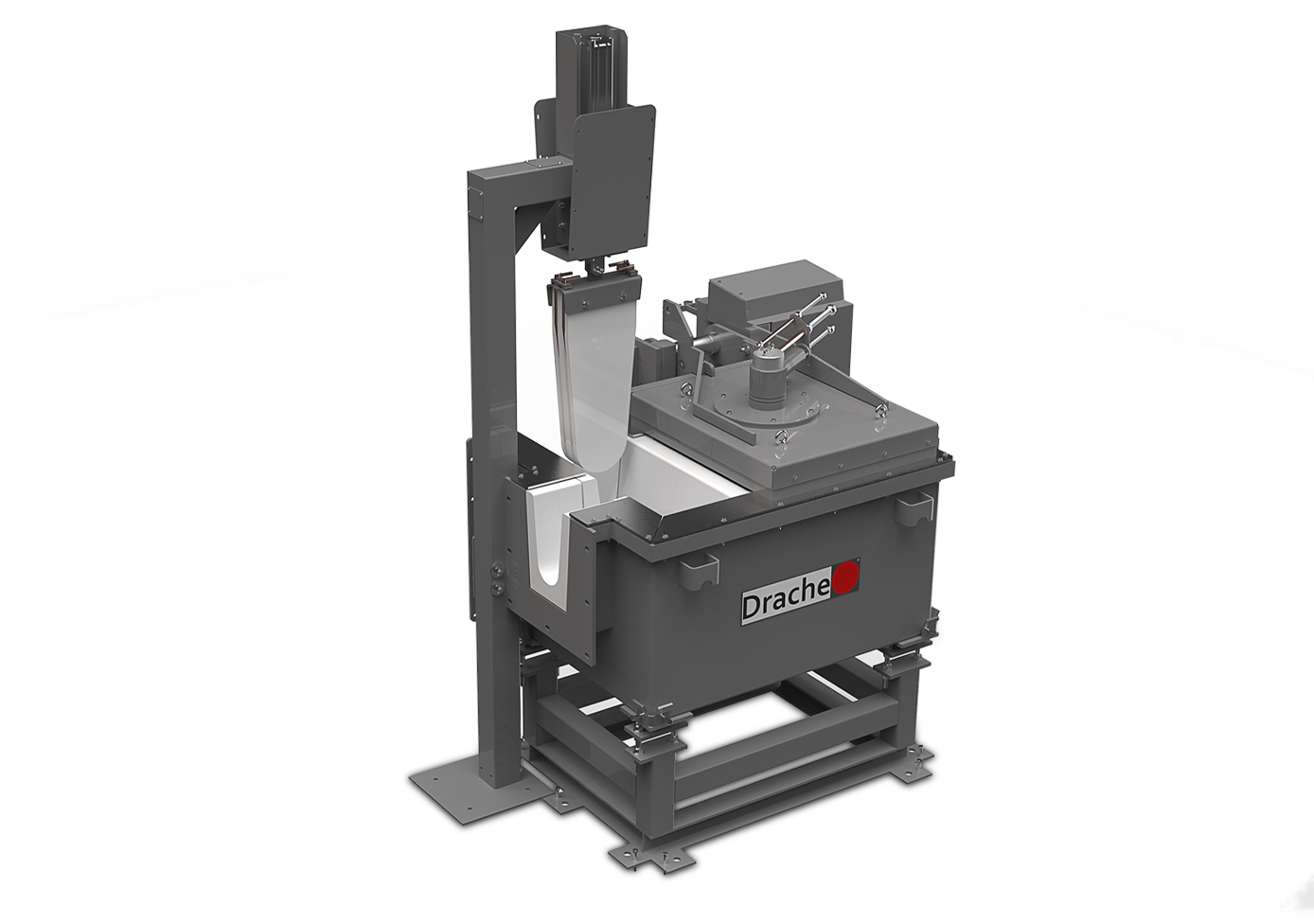

Our filterbox systems are used in aluminium DC and continuous casting. We offer filterboxes in all common sizes, single boxes as well as double boxes, covering the full range of flow rates. Drache filterboxes are characterized by small heat losses and a low steel shell temperature. All filterboxes follow a modular concept. The filterbox itself, the preheating lid das well as the filterbox’s stand are independent of each other, allowing a quick change of the box between casts if necessary. All filterboxes can be customized to meet the exact customer requirements.

Drache Filterboxes Keyfacts

Drache Filterboxes have a number of advantages.

Key Advantages

- Robust, modular design

- Low heat loss, low steel shell temperature

- Automatic, „hands-free“ drainage (optional)

- Selection of preheating systems

- Option for customer and project-specific designs

Have we sparked your interest? Arrange a free consultation with our experts.

Technical Data

- Sizes: double 26“, double 23“, 26“, 23“, 20“, 17“, 15“, 12“, 9“, 7“

- Designs for double filterboxes: 3

- Drainage options: drain launder, drain hole, forward draining

- Customer specific inlet / outlet configuration: yes

- Height-adjustable: yes

- Preheating systems : Drache Flow Heater, gas-fired preheating system, electrical resistance

- heating

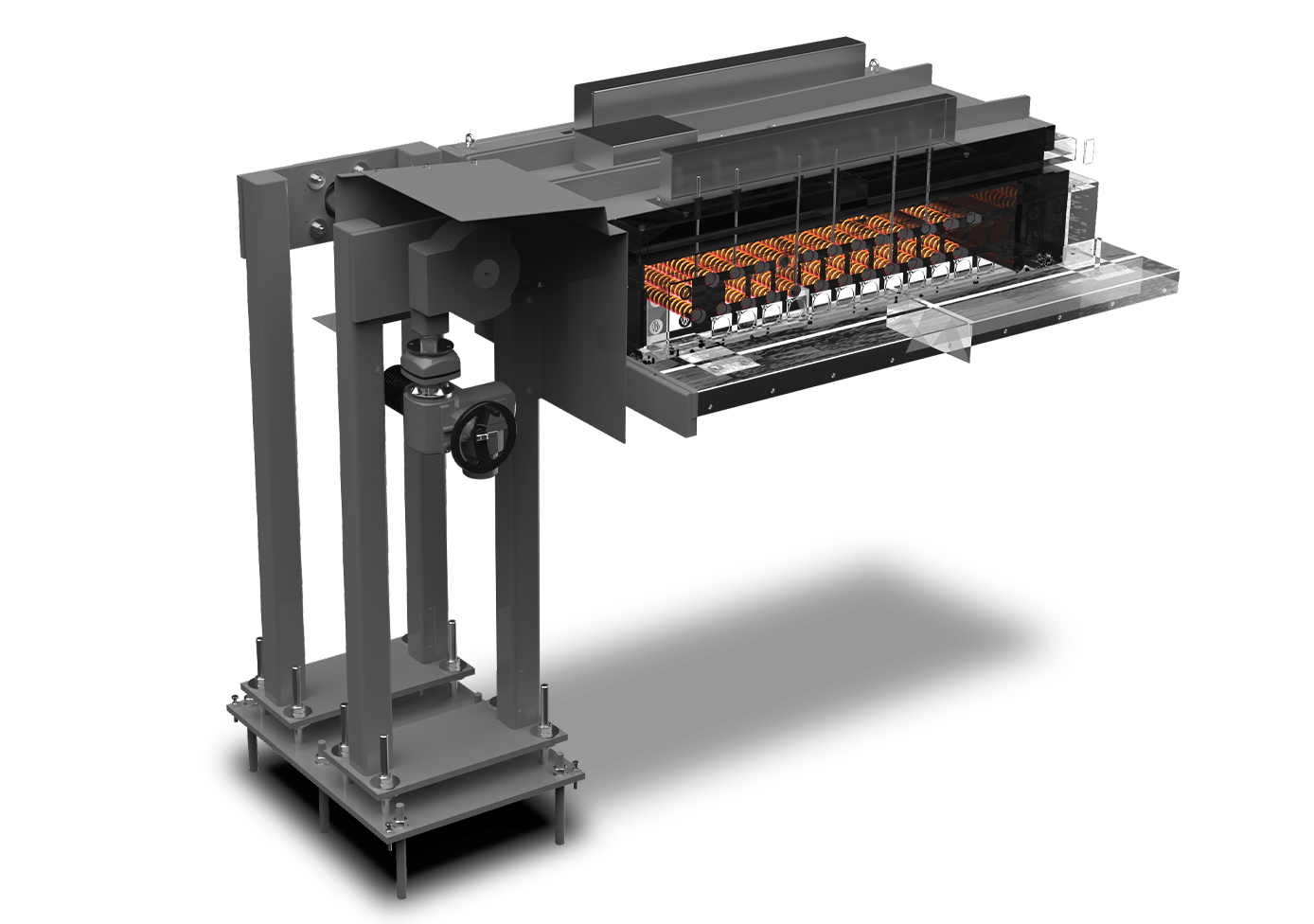

Drache Flow Heater

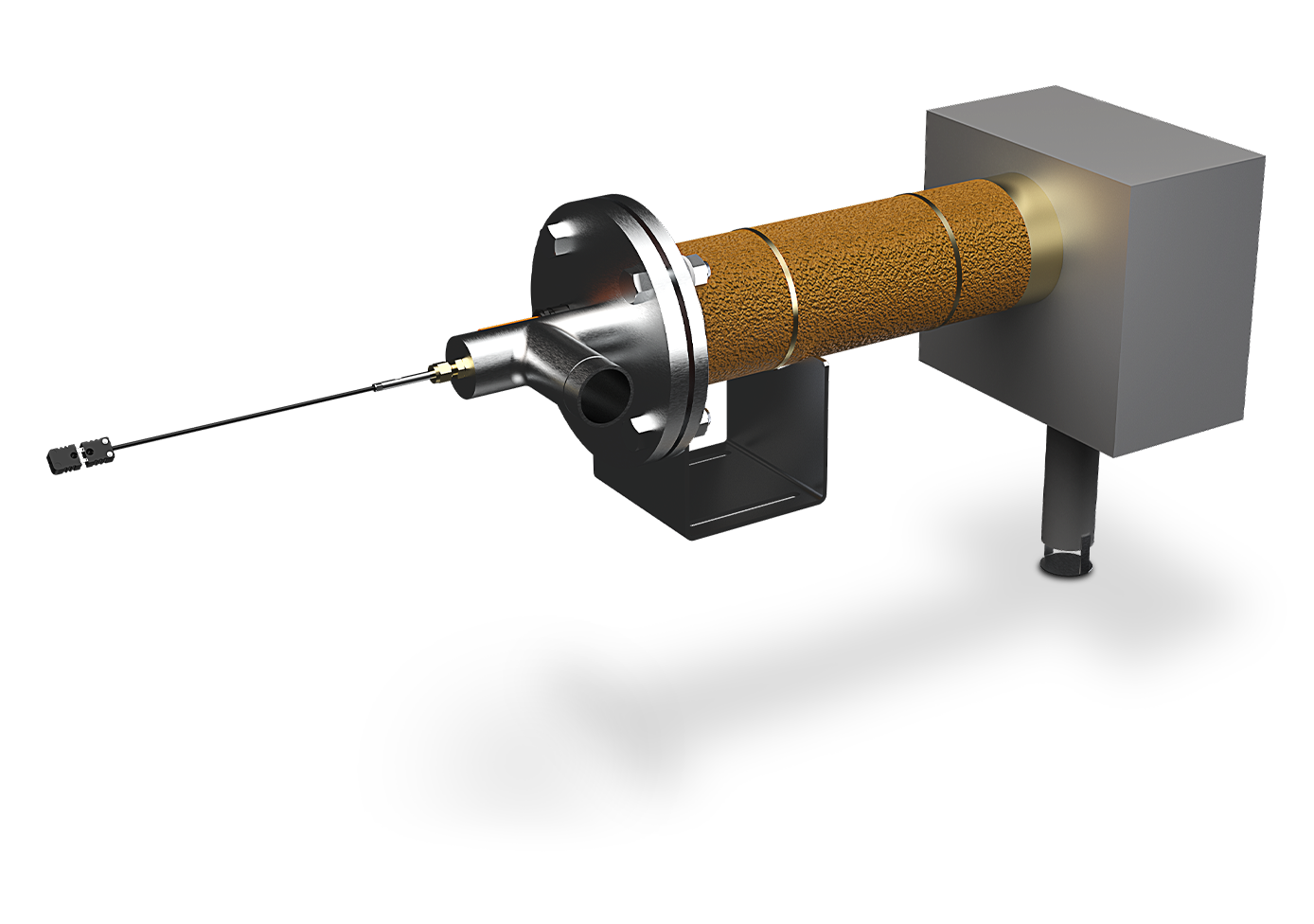

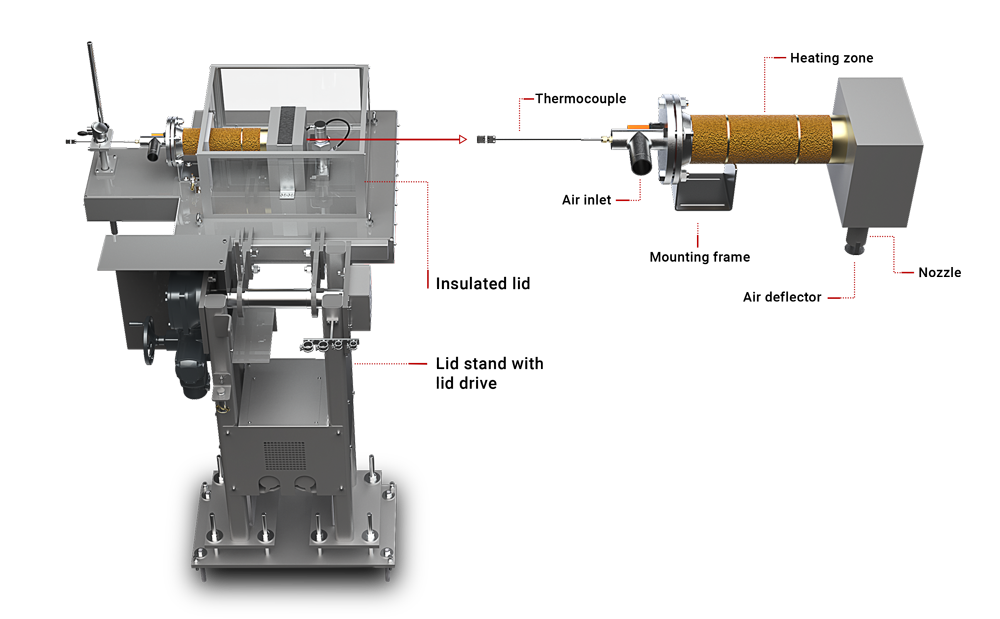

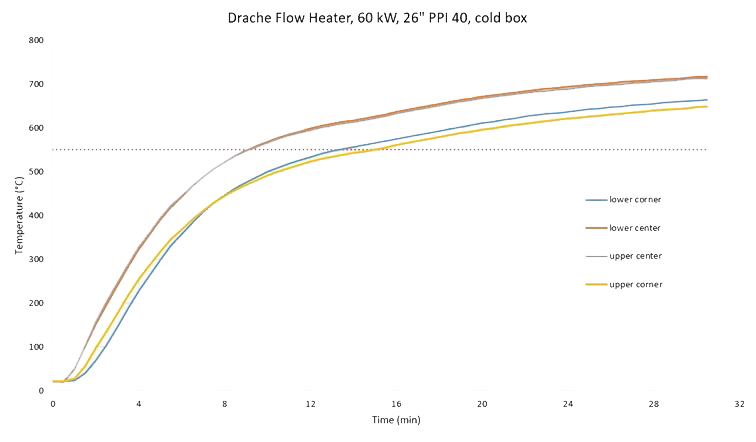

The Drache Flow Heater is an advanced electrical preheating system to preheat CFFs inside a filterbox in aluminium DC and continuous casting. It heats up air to approx. 1100°C which flows through the CFF, giving a fast and uniform preheating. The Drache Flow Heater is suitable for all filter sizes up to 26” and filter porosities up to PPI 60.

Drache Flow Heater Keyfacts

The Drache Flow Heater combines the advantages of gas-fired and electrical preheating systems.

Key advantages:

- Fast and efficient

- Very uniform preheating

- No combustion gases: no NOx, no CO2, no other exhaust gases

- No generation of moisture

- Easy to install – only electrical power supply is required

Have we sparked your interest? Arrange a free consultation with our experts.

Technical Data

- Power: 60 kW, 40kW

- Max air temperature: 1100 °C

- Air flow: 135 m3/h (60 kW Flow Heater), 90 m3/h (40 kW Flow Heater)

- Power supply controlled by a phase angle controller

- Protection against overheating

- Required power supply: 400 V 50 Hz or 480 V 60 Hz

- Required current: 80A (40 kW Flow Heater), 125 A (60 kW Flow Heater)

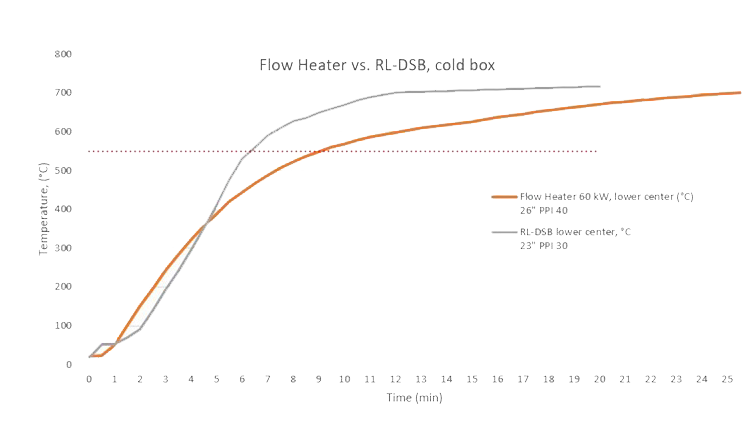

Flowheater 26P40 Preheating Curve

Flow Heater - RL-DSB Comparison Curve

Gas-fired Preheating System

The Drache gas-fired preheating system is a proven filterbox preheating system operating in many casthouses around the world. It is suitable for filterbox sizes of 17“ and bigger. The system consists of a burner with a number of secondary air holes, giving a very uniform heat distribution in the box and the filter. This achieves a very homogenous preheating of the CFF within 15-25 minutes.

Gas-fired Preheating System Keyfacts

The Drache gas-fired preheating system preheats fast and efficiently.

Special Advantages

- Complete preheating system, consisting of burner, burner control panel, and connection

hoses - Very homogenous preheating by secondary air

- Reliable, proven system

- Fast and efficient

- Suitable for filter porosities up to PPI 70

Have we sparked your interest? Arrange a free consultation with our experts.

Technical Data

- Power range: 30 – 70 kW

- Power / heating stages: 2

- Gas supply: natural gas or LPG

- Gas control panel included in scope of supply: yes

- Gas consumption: 2,5 – 7,5 m3/h (for natural gas, depending on heating value)

- Compressed air consumption: approx. 7 – 21 m3/h (depending on power setting)

Electrical Resistance Heating

Heating lids equipped with electrical resistance heating elements are especially suitable for smaller and shallower filterboxes, using CFFs with a porosity up to PPI 40. The CFF is preheated by radiation of the heating elements.

Electrical Resistance Heating Keyfacts

Heating lids with electrical resistance heating are robust and easy to install.

Special Advantages

- Power 15-25 kW, depending on the filterbox size and CFF porosity

- Electric control cabinet included

- Temperature monitoring of the heating elements to prevent overheating

- Easy to install and operate

Have we sparked your interest? Arrange a free consultation with our experts.

Technical Data

- Power: approx. 15- 25 kW

- Project-specific design possible: yes

- Temperature monitoring included: yes

CONTACT

If you need help or have a question regarding filters, system construction,

another product or even a custom solution, please fill out the contact form below.