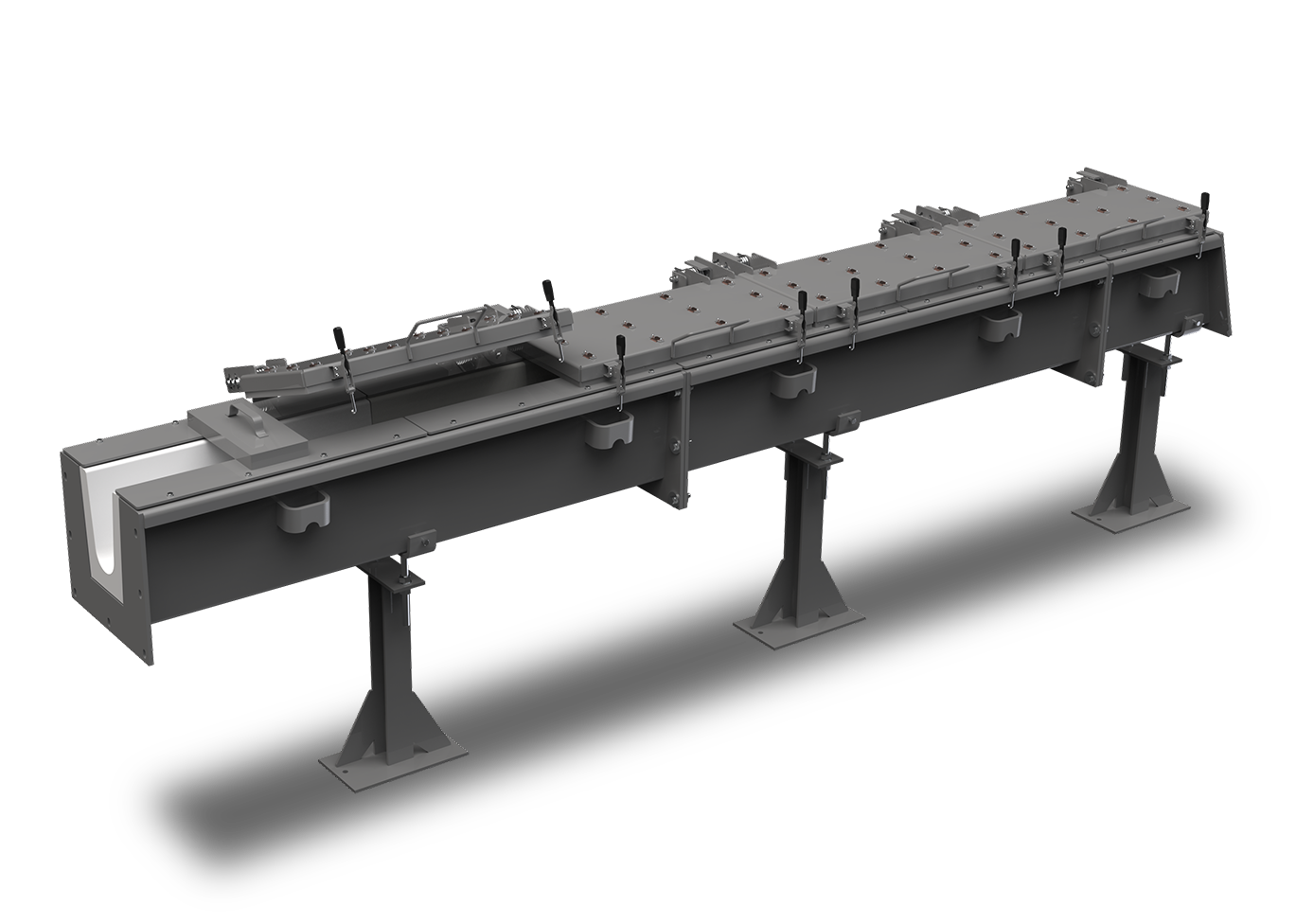

Launder

We supply launder systems for aluminium DC casting as a complete package. This includes the selection of a suitable launder cross section, the complete engineering, manufacturing, and, if desired, the installation on site. All our launder systems are optimized for a minimized heat loss, low steel housing temperature, and a calm metal flow.

Drache Launders Keyfacts

Drache offers custom-tailored launder systems for every application.

Special Advantages

- Carefully selected launder cross-section, suitable for the given casting speed

- Low heat loss and low steel shell temperature thanks to a highly efficient insulation

- Robust, long-lasting design

- Option for lids, preheating system, and launder dams

- Estimation of heat loss of the launder system in the project phase

Technical Data

- Refractory material: Drache Fused Silica

- Number of Drache standard launders: 6 (Q081, Q020, Q003, Q050, Q066, Q191)

- Customized launder cross-section possible: yes

- Dry insulation possible: yes

- Insulation with microporous board, dry insulating granulate or insulating concrete

- Lids with preheating system: yes (optional)

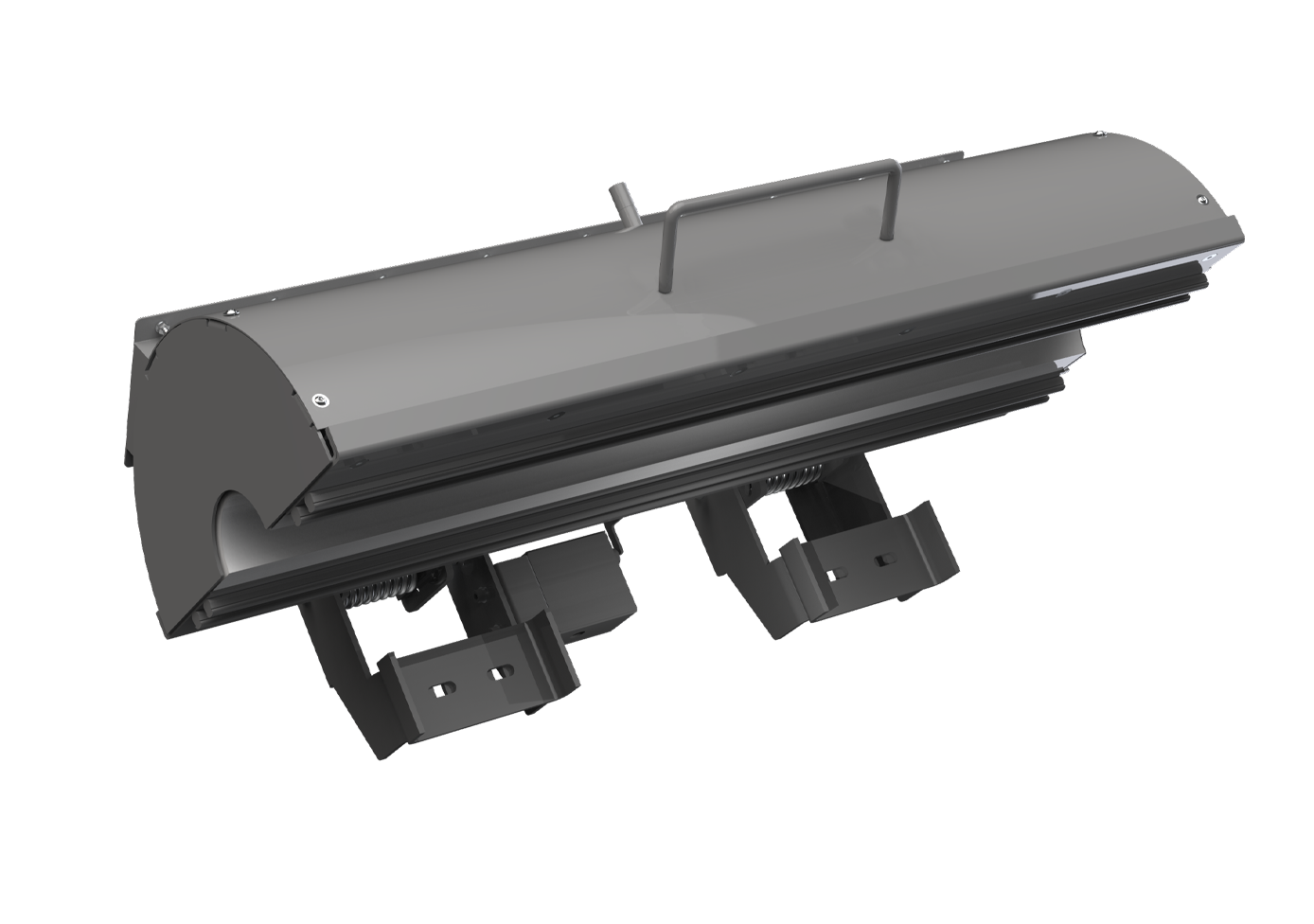

Launder Lids

To minimize the heat loss of the lauder system, lids can be installed. By reducing the heat loss due to radiation of the bath surface, the heat loss per meter of launder can be reduced significantly. Drache launder lids can optionally be equipped with a preheating system.

Drache Launder Lids Keyfacts

Drache offers launder lids for its launder systems

Special Advantages

- Reduce the heat loss of the launder

- Robust, long-lasting insulating cushions installed in the lids

- Easy opening and closing, either manually or pneumatically

- Option of preheating system

Technical Data

- Manual operation: yes

- Option for pneumatic opening / closing: yes

- Insulation individually replaceable: yes

- Option for preheating system: yes

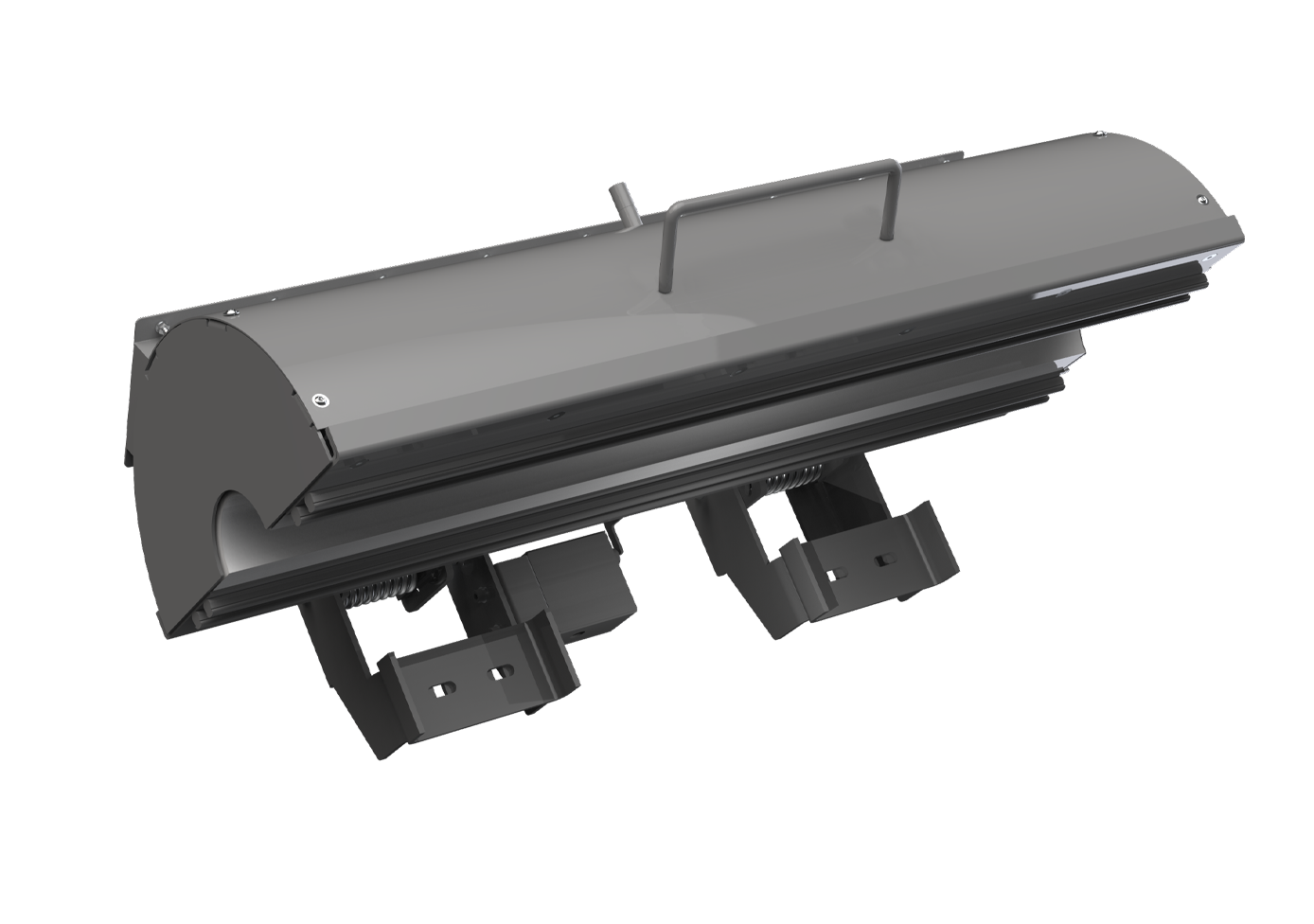

Heated Launder Lids

The launder lids can be equipped with an electrical preheating system upon request. Due to that, the heat loss can be further reduced at the beginning of the cast.

Drache offers to different systems:

- Hot air blower

- Electric resistance heating elements

Hot Air Blower Keyfacts

A powerful, easy-to-use and robust design

Special Advantages:

- Easy integration into the process thanks to the compact design

- Integrated fan, no external air supply necessary

- Option for remote control via an analog interface

- Relatively small number of heaters necessary (one every 3-4 meters)

Technical Data:

- Power: 10-11kW

- Built-in overheating protection: yes

- Temperature control: yes

Electrical Resistance Heating Keyfacts

Minimized heat loss through electrically heated lids

Special Advantages:

- The heating system can operate while the cast is running, reducing the heat loss per meter of launder.

- Reduces the heat loss at the start of the cast and at low casting speeds.

- Temperature monitoring of the heating elements

- Heating elements can be controlled individually

- Supply includes the electric cabinet with controls, power supply, and monitoring of the heating elements

Technical Data:

- Heating power per meter: approx. 5 – 7,5 kW (depending on launder cross-section)

- Temperature monitoring: yes

- Temperature control: yes

- Pneumatically driven lids

Air blower heated launder lids

Restistance heated launder lids

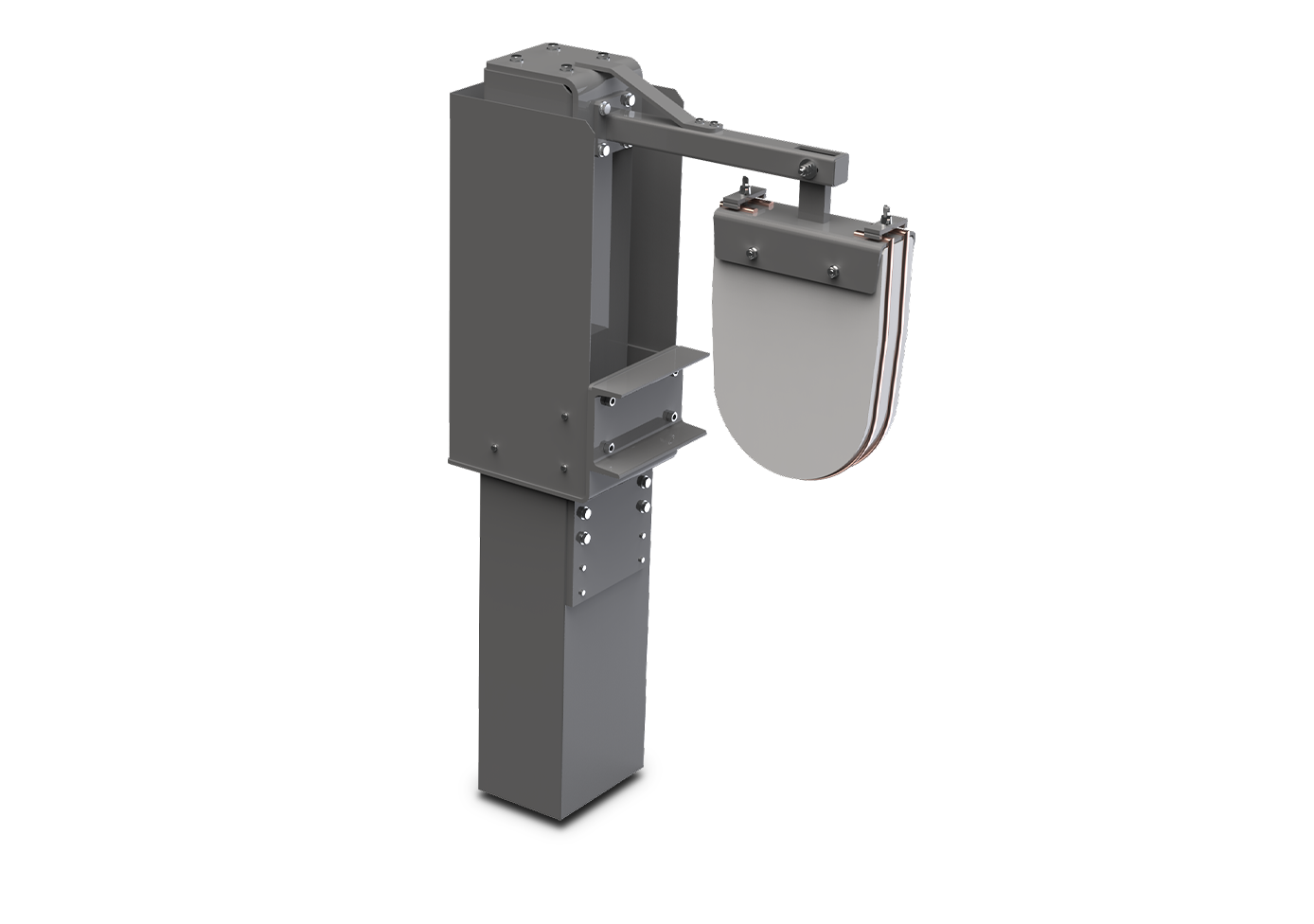

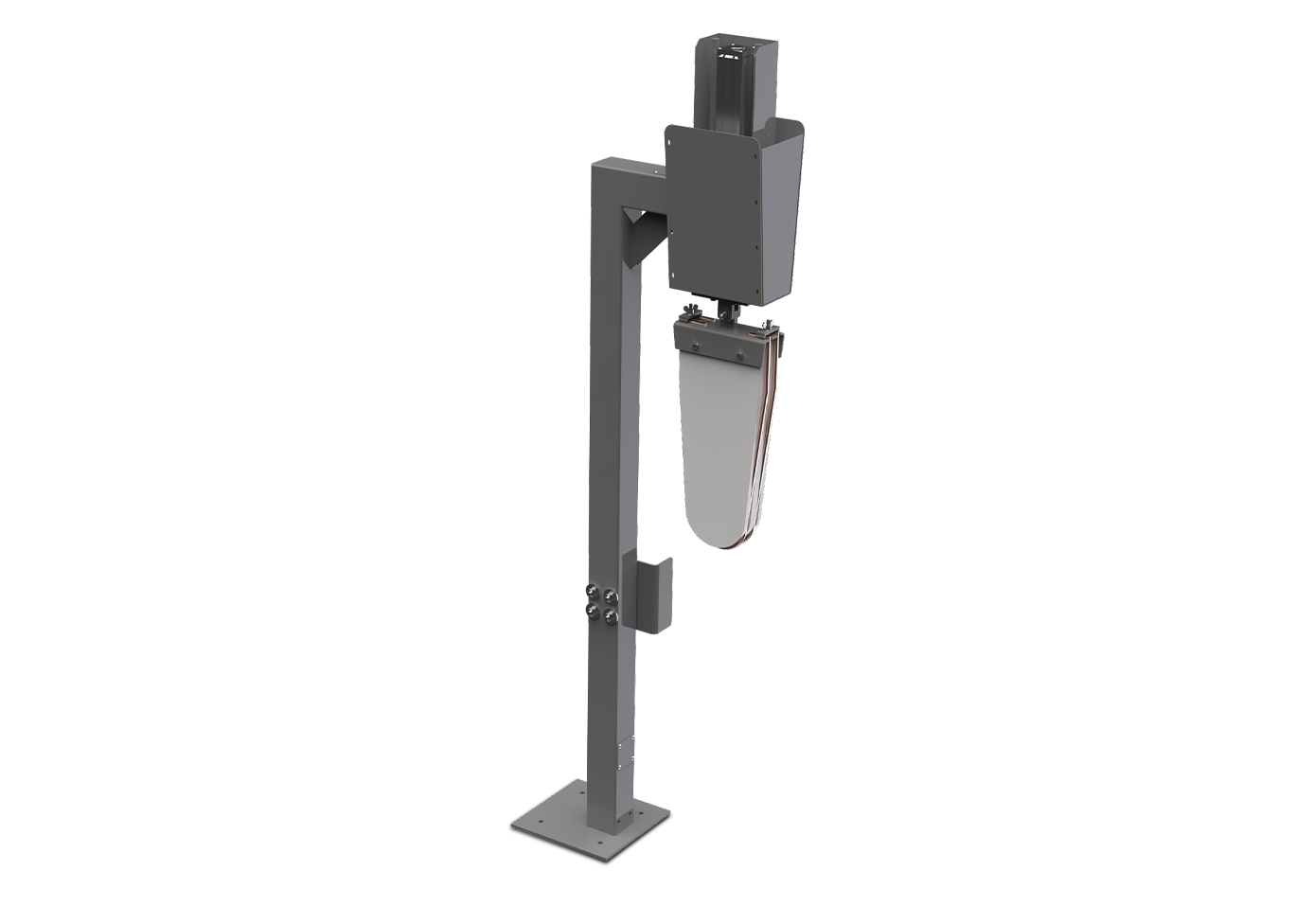

Launder Dams

In addition to launders and launder lids, Drache also offers launder dams. The dams are available for manual operation as well as pneumatically driven. All dams consist of a calcium silicate dam board with a machined groove, a sealing rope, and a holder for the dam.

Launder Dams Keyfacts

Pneumatically driven and manual dams

Special advantages

- Robust design, manual operation or pneumatically driven

- Sealing rope can be changed without tooling and while wearing gloves

- All pneumatically driven dams have a double sealing rope

- Tilt protection for manual dams

- Pneumatically driven dams can be controlled by a 5/3 or 5/2 way valve

Technical Data

- Dam thicknesses: 100mm, 75mm, 50mm

- Position of pneumatic cylinder for pneumatically driven dams: on top, on the side

- Heat protection for cylinder: yes

- Tilt protection of manual dams: yes

- Option of customized design: yes

- Sealing rope can be changed without tooling: yes

Level Control Dams

Level Control Dams allow an exact control of the opening position of the dam inside the launder; thus the flow of metal can be controlled. This is possible by using an electric cylinder, which can be exactly positioned between the fully open and fully closed position. The dam plate itself is machined from calcium silicate with a double groove for the sealing rope.

Level Control Dam Keyfacts

Flow control by using an electric cylinder

Special advantages

- Control of the metal flow

- Built-in end position switches

- Sealing rope can be replaced without tooling and while wearing gloves

- Constant opening / closing speed

Technical Data

- Open / closing speed: selected depending on the required control of the flowing metal

- Option for customized designs: yes

- End position switches: yes

- Position detection: optional

- Sealing rope can be changed without tooling: yes

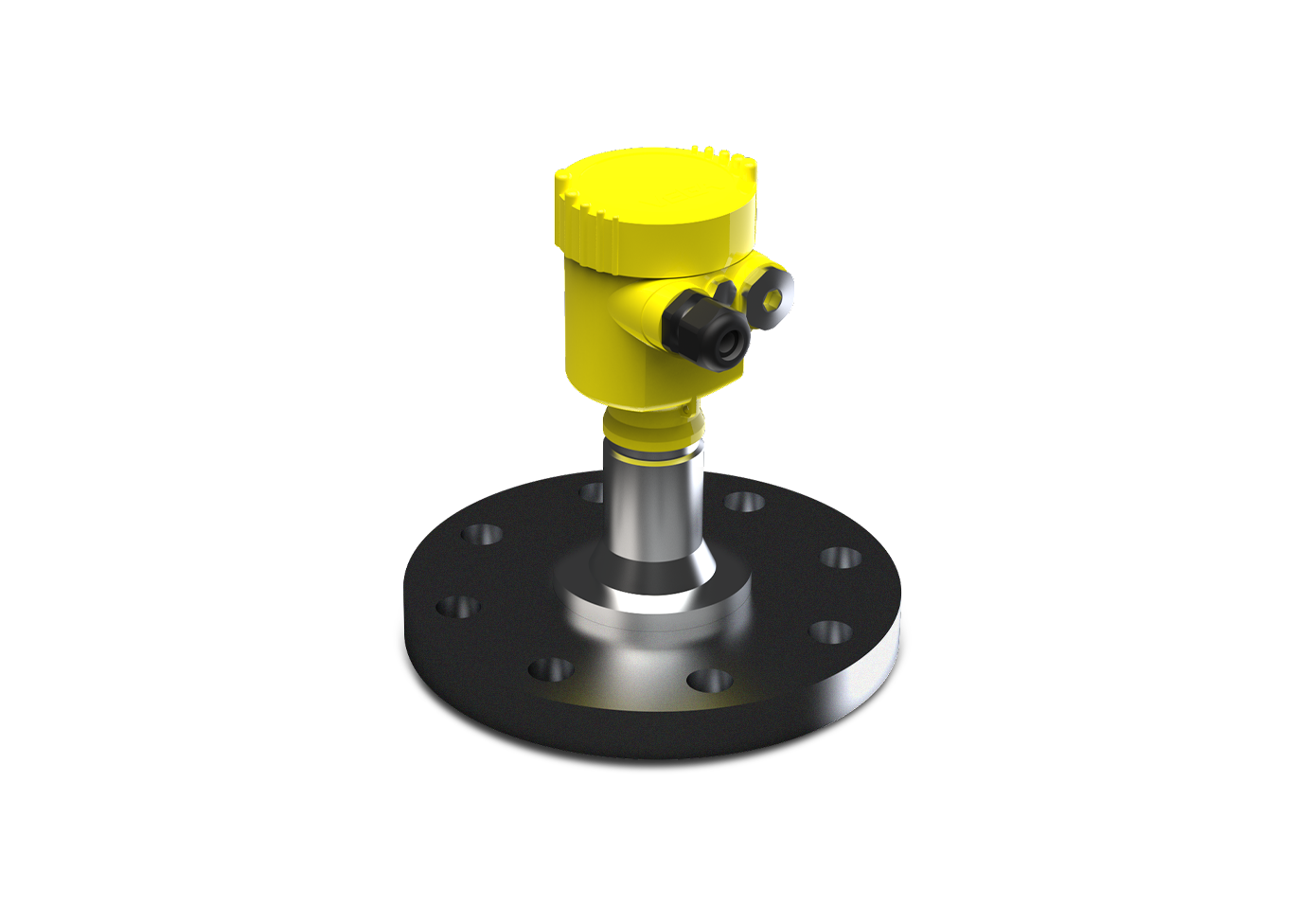

Metal Level Measurement

The metal level of the aluminium inside the launder can be monitored by the help of radar sensors. These are placed on a holder above the launder, allowing an accurate metal level detection.

Metal Level Measurement Keyfacts

Fast and accurate metal level measurement

Special advantages

- Accurate measurement

- Easy to install

- Low maintenance

Technical Data

- Opening angle of radar cone: 3°

- Cooling needed: no

- Programming / Calibration: via integrated display or via app plus Bluetooth

- Wear parts: none

CONTACT

If you need help or have a question regarding filters, system construction,

another product or even a custom solution, please fill out the contact form below.