System engineering

We supply a wide range of engineered products for aluminium casthouses. These include filter boxes and launder systems for aluminium DC casting as well as transport crucibles for aluminium foundries. The relining of deep bed filters and degassers is part of our ‘all-inclusive’ service package. We cover the full range of services for our engineering products. From the initial design and creation of 3D drawings up to the installation and commissioning on site, we are at your side.

Our commitment to quality

Our service

We cover the full range of services for our engineered systems. We assist you throughout the entire process – from the initial design and creation of 3D drawings through the manufacture of parts and their assembly to the installation and commissioning on site. Our products and services meet the highest quality standards and we can be reached at short notice.

Design

3D drawing

Production

Installation & start-up operation

Large-scale construction

Drache produces a wide range of engineered systems for the aluminium industry. These include filter boxes and launder systems for aluminium DC casting as well as transport crucibles for aluminium foundries.

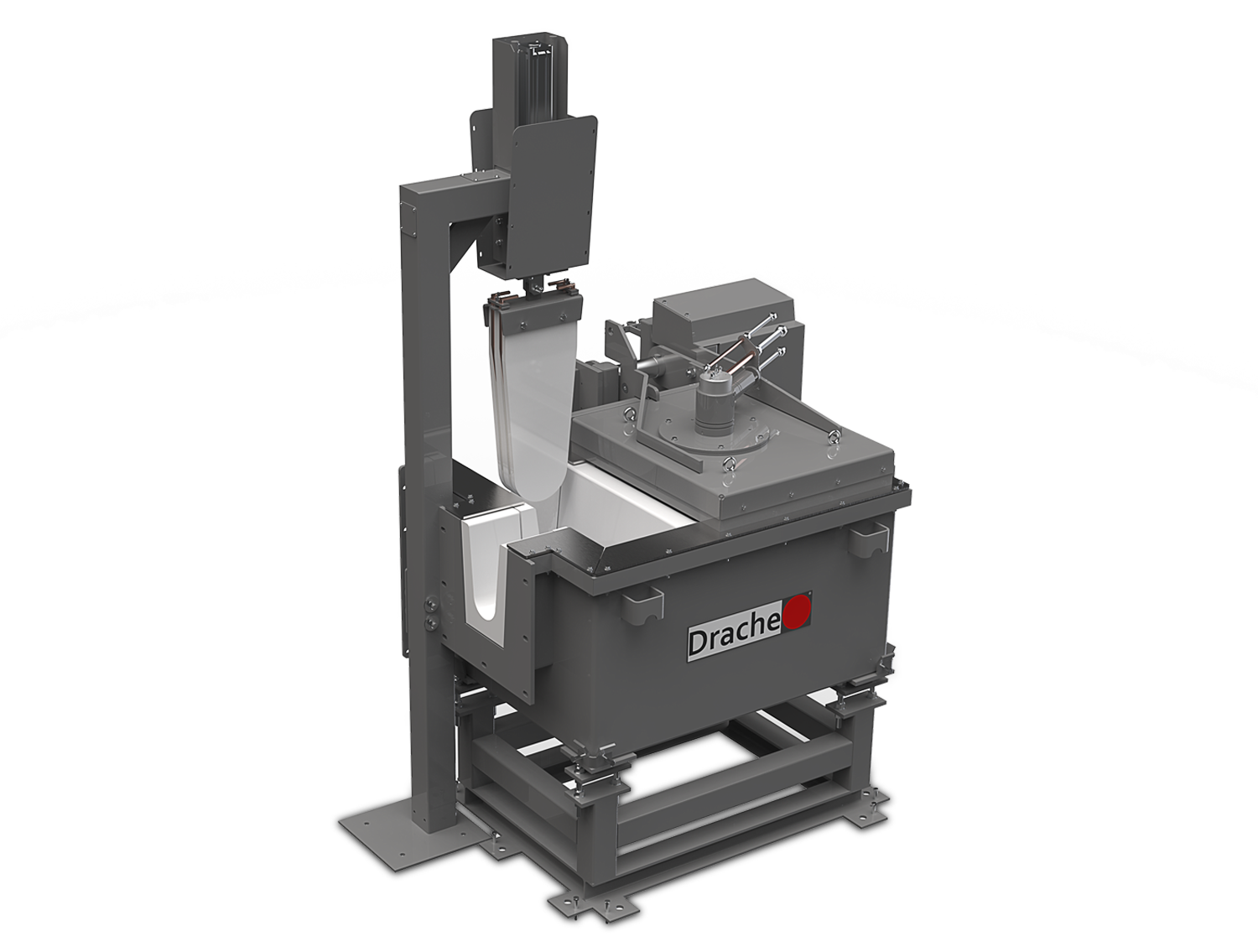

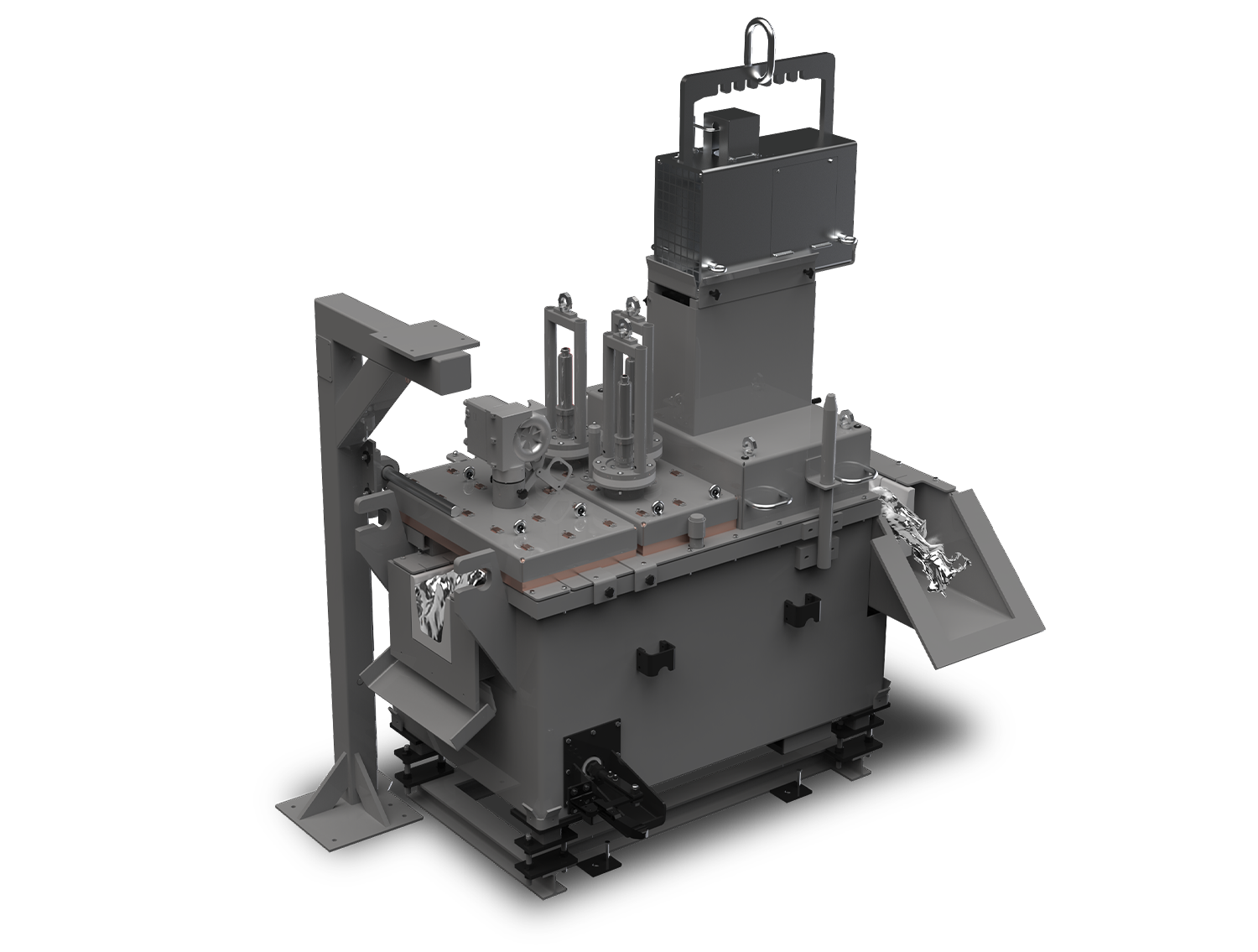

Filter box liners

Our filter box systems are used in aluminium DC and continuous casting. We provide expert support throughout the entire process, from the initial design through the complete engineering and production in-house to the installation, start-up, and operator training. One of the features of our filter box systems is their easy use and robustness. They also have low heat losses combined with a low steel housing temperature. We supply filter boxes with gas heating systems, or, as an alternative, with electric heating systems to preheat the ceramic foam filter. Our filter box systems also have a modular design. This means that the filter box body, lid (with lid stand), pre-heating system, and stand are independent of each other. This makes a rapid replacement between two casts possible. Our filter boxes are available in all standard sizes 7“, 9“, 12“, 15“, 17“, 20“, 23“, and 26“. In general, all filter boxes are produced in accordance with our customers’ individual requests, so customized solutions are also possible.

Are you interested in our filter box systems? Arrange a free consultation with our experts.

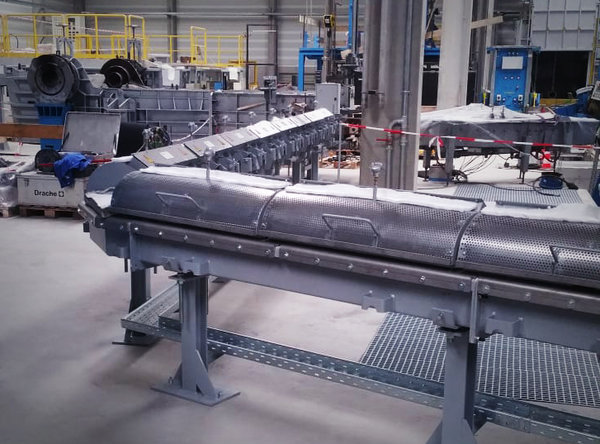

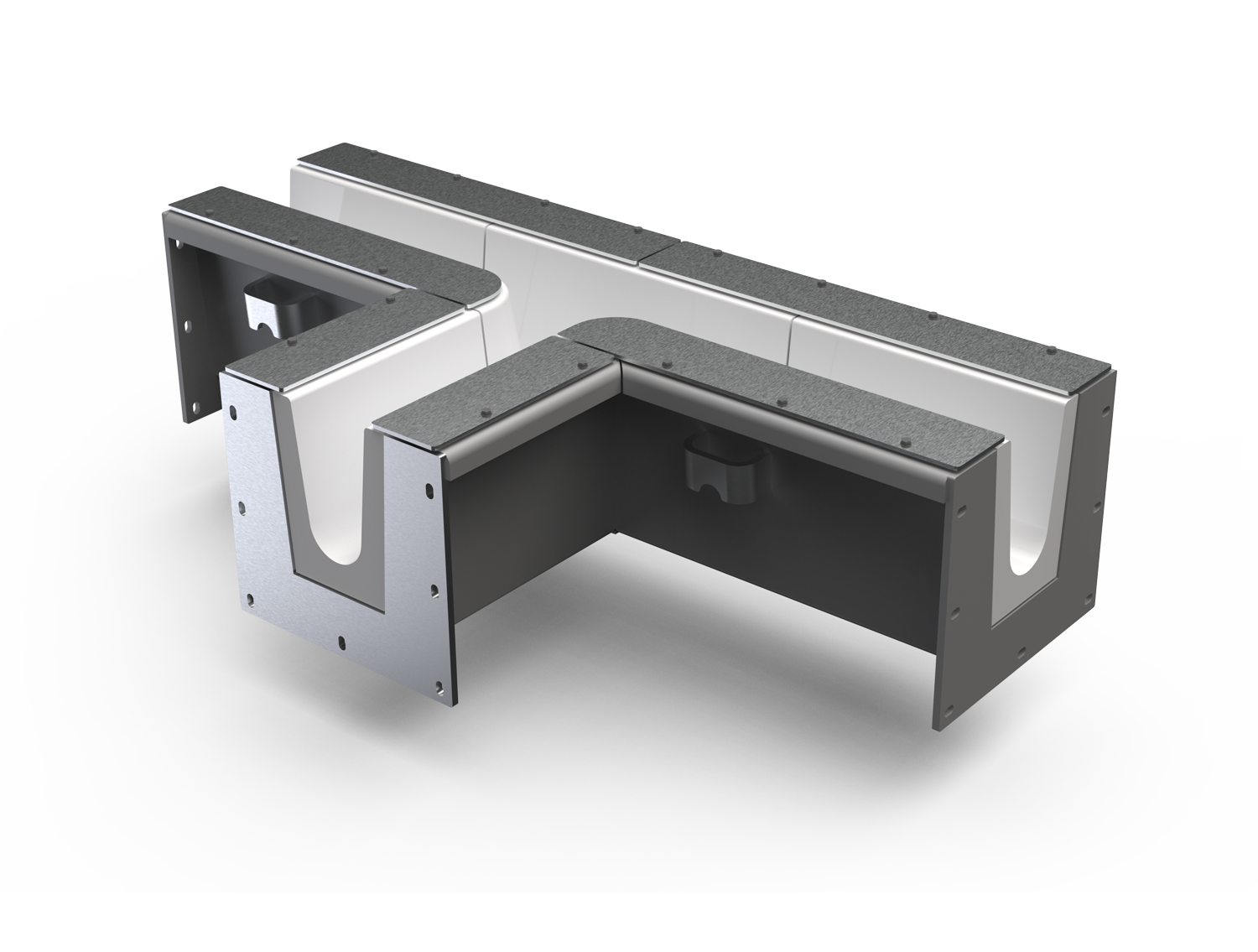

Launder systems

We supply launder systems for aluminium DC casting as a complete package. This includes the selection of a suitable launder cross section, the complete engineering, manufacturing, and, if desired, the installation on site.

All our launder systems are optimised for a minimised heat loss, low steel housing temperature, and a calm metal flow. If requested, the launders can be equipped with covers and a pre-heating system. Our launder covers with electric heating allow the launder system to be preheated prior to casting. This minimises the heat loss during the initial casting process.

Our wide range of launder segments includes small segments for continuous casting, large segments for billet and rolling ingot casting as well as transfer launders. The right launder cross-section is selected in consideration of the given casting speed. If operated and maintained properly, our launder segments will achieve an excellent service life combined with minimal maintenance costs and a quick return on investment.

Are you interested in our launder systems? Arrange a non-binding consultation with our experts.

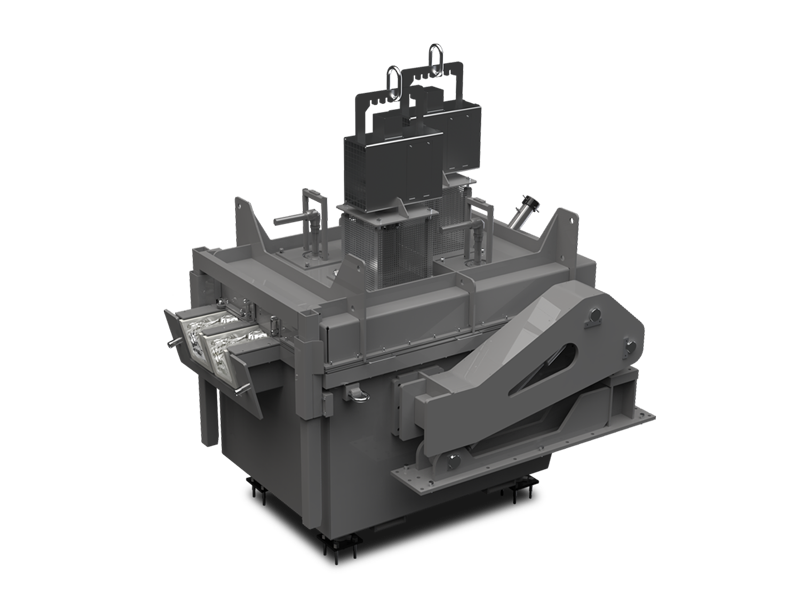

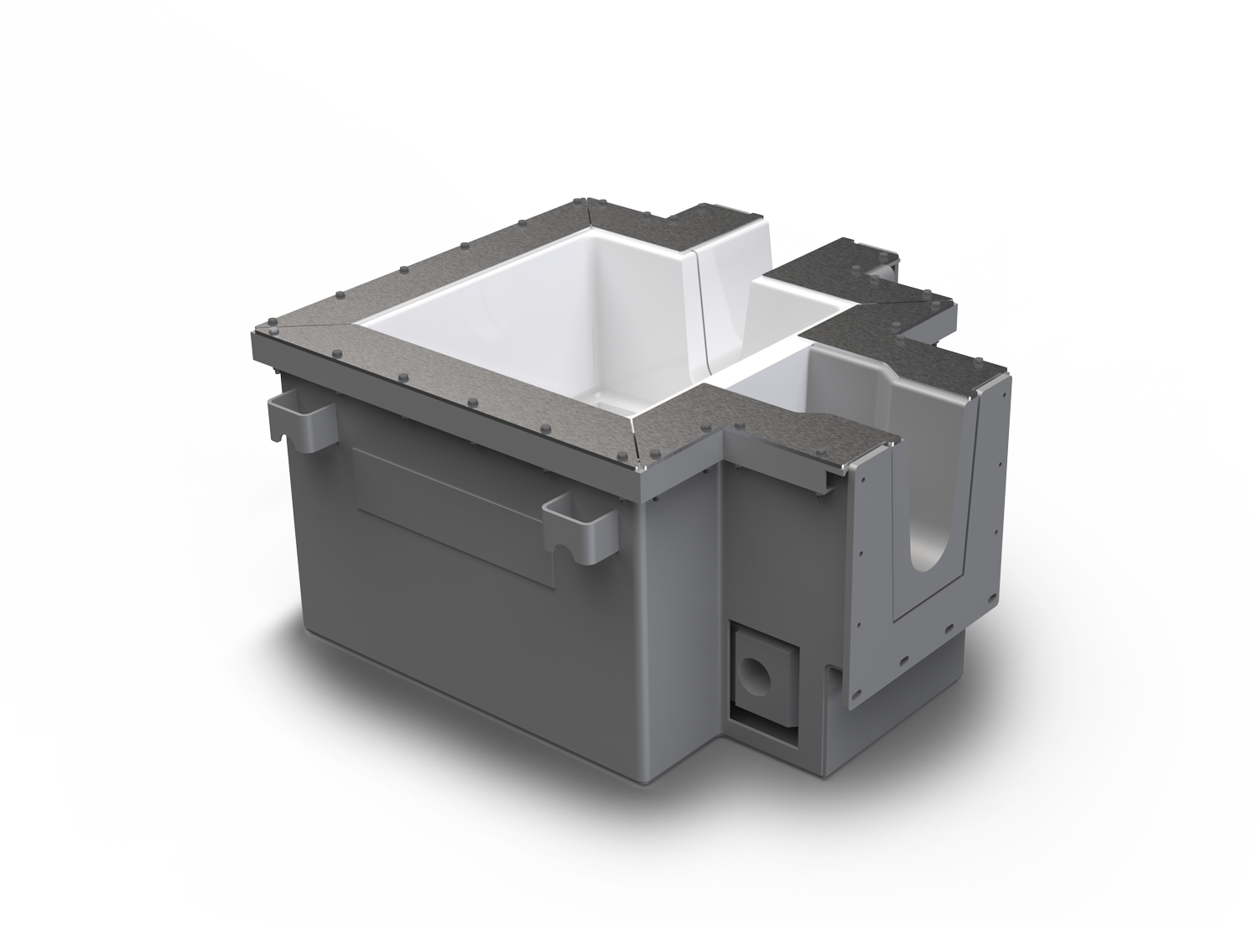

Large pre-cast shapes

In addition to ‘standard components’ such as filter boxes, launders, casting spouts, and hot top rings, we also manufacture large pre-cast shapes for applications in aluminium casting. This includes liners for deep bed filters, degassers, casting tundishes, and transport crucibles. All parts are cast, fully dried, and fired in our production facility. This means they are delivered ready to use. With our ‘all-inclusive’ service package, the relining can either be done at the Drache workshop or directly on site at the casthouse. For a complete relining, we use high-efficiency insulation materials alongside our own proven parts. This minimises the heat loss for degassers, deep bed filters, and transport crucibles.

Are you interested in our large pre-cast shapes? Arrange a non-binding consultation with our experts.

On-site service

In addition to our wide range of engineered products for aluminium casthouses and foundries, we also provide a number of services. This among others includes our comprehensive and custom consultation. As for all our products, we ensure that our services meet high quality standards. With our ‘all-inclusive service package’, we also offer installation and initial start-up on site.

Are you interested in our extensive products and services? Arrange a non-binding consultation with our experts.

CONTACT

If you need help or have a question regarding filters, system construction,

another product or even a custom solution, please fill out the contact form below.